What We Can Do For You

Industry Certified Castings, Forgings, Precision Machining, Wiring Harnesses, Composites, PCBs, Sheet Metal, Fabrication, Tubes, Surface treatment, and Distribution inventory items for Aerospace, Defense, Industrial Machinery and Medical devices

Aluminum Investment Castings, produced using the lost wax method. Size ranging from 25 x 10 x 5 mm (Min.) to 600 x 300 x 200 mm (Max)

Weight ranging from 45 grams to 45 kilograms for Steel and 15 grams to 15 kilograms for Aluminum.

NadCap certified NDT.

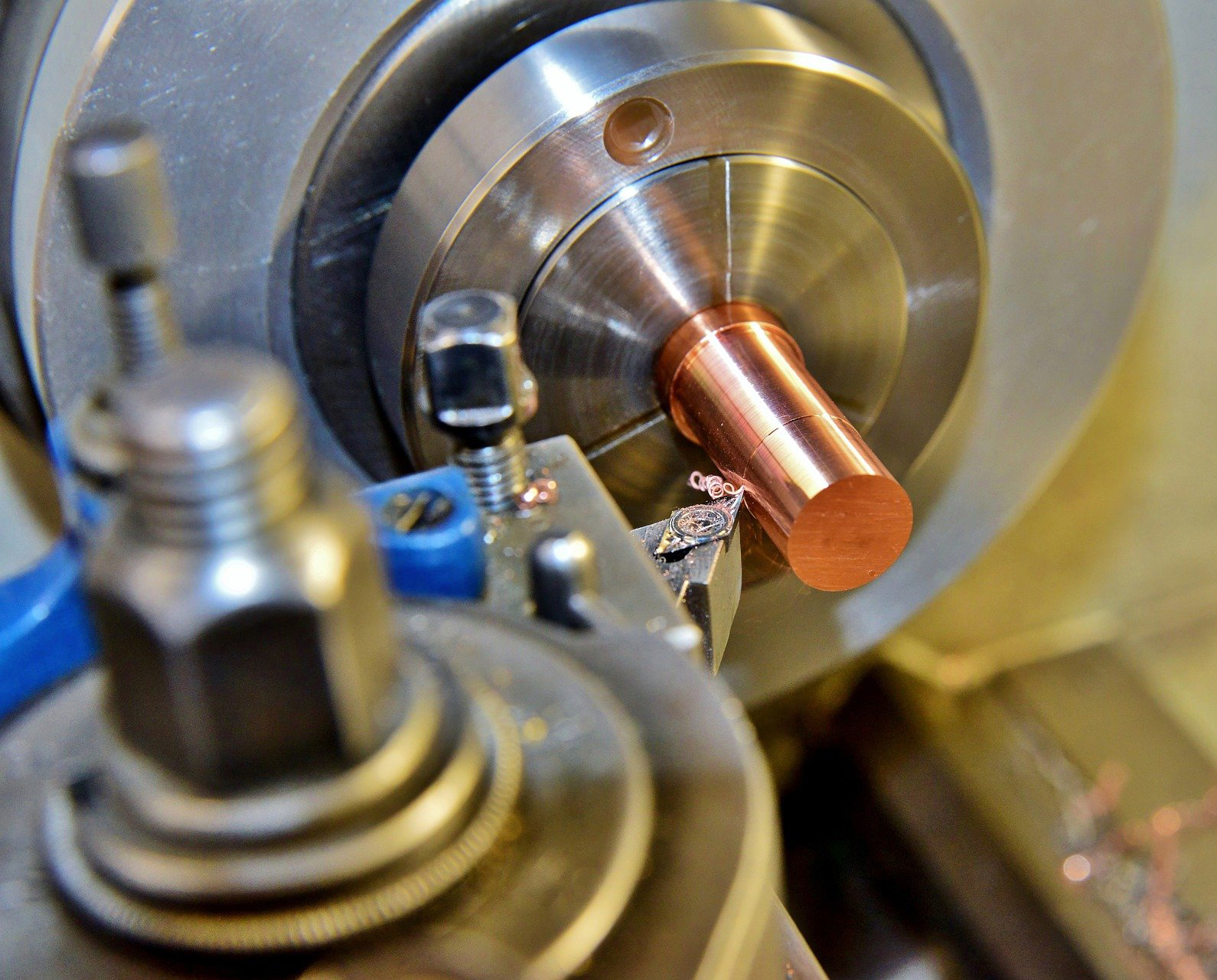

3 axis and 4 axis CNC machines, CNC controlled conventional and sliding head lathe machines, CNC Controlled Turn mills,Vertical Milling Centers

Secondary operations including but not limited to grinding, polygon milling, spline and thread rolling, and honing machining.

Turning: Max length: 400 mm, Max weight: 60 kg, Turning Dia: 2 mm to 250 mm

Turnmill: SHS: Dia 0.5 mm to 20 mm, max 250 mm length

Fixed: Dia 2 mm to 200 mm, max length 350 mm

Milling: Torque: 340 Nm, 10000 RPM, Bed Size: 711 x 1626 x 813 mm

Electroplating:

Electroless Plating:

Anodization:

Conversion Coating:

Passivation:

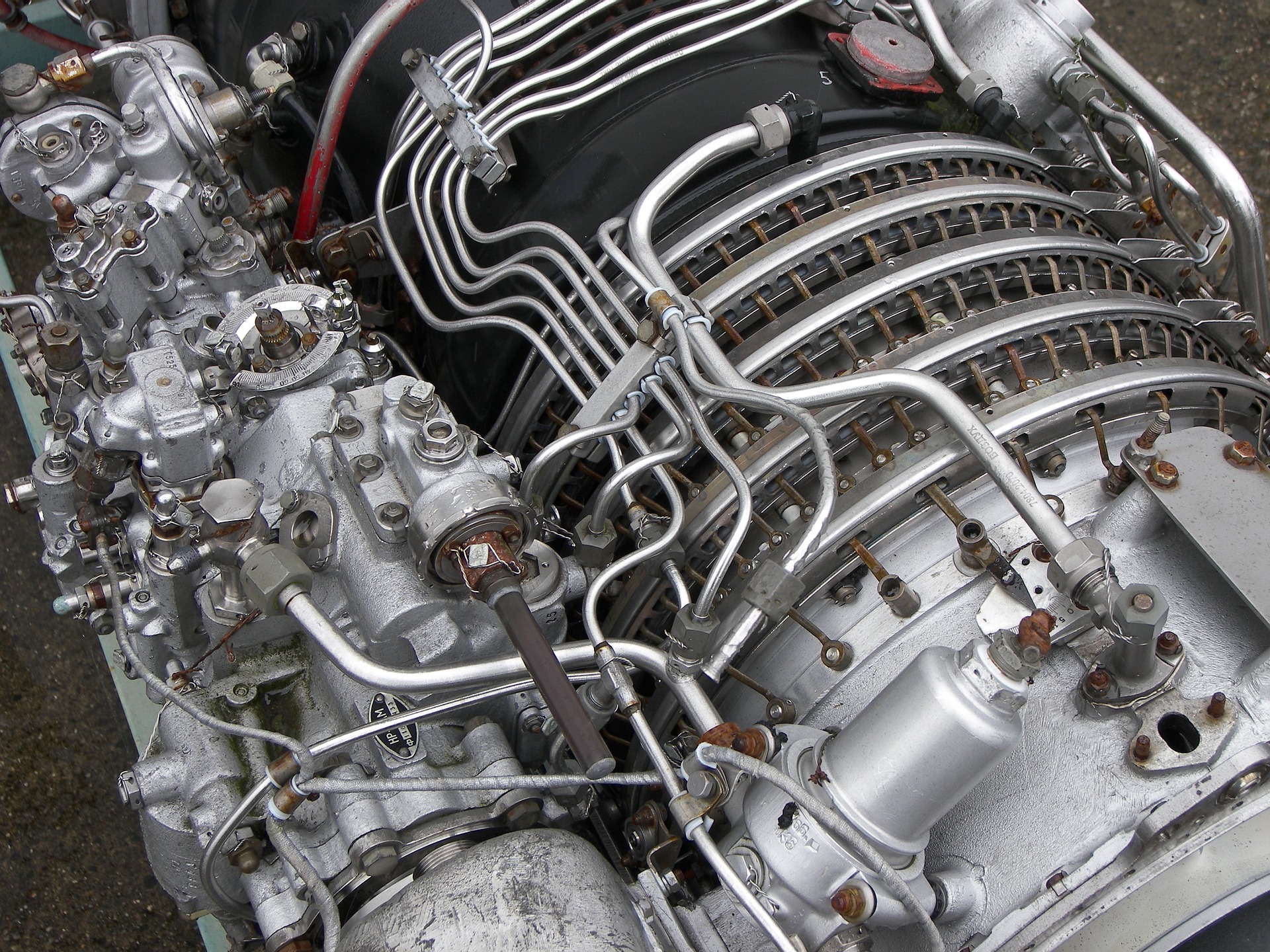

We provide all aerospace tubes, ducts and heat exchanger for your specific need.

Please contact us today to see where can we help you.

Our group of suppliers have US presence to meet your warehouse distribution needs and support VMI requirements. Our contract manufacturers use this to provide added value to our end customers.

Product Range: 2 kg -300 kg manufacturing critical products like Crankshafts, Steering Knuckles, Front Axle Beams, Differential Cases, Crown Wheels and Hubs

Continuous Hardening & Tempering Quench type Furnace (Capacity of 4 Ton / Hr) equipped with Instrumentation Panel for temperature controls & recording with SCADA software with data logging & history recording.

Our expertise lies in manufacturing critical harnesses like ABS ECU, Engine Harnesses, VTS ECU harnesses, FDSS ECU harnesses, and battery cables ranging from 16 sq. mm. to 200 sq. mm. We cater to Automotive, Farm, Construction, Industrial, and Medical sectors.

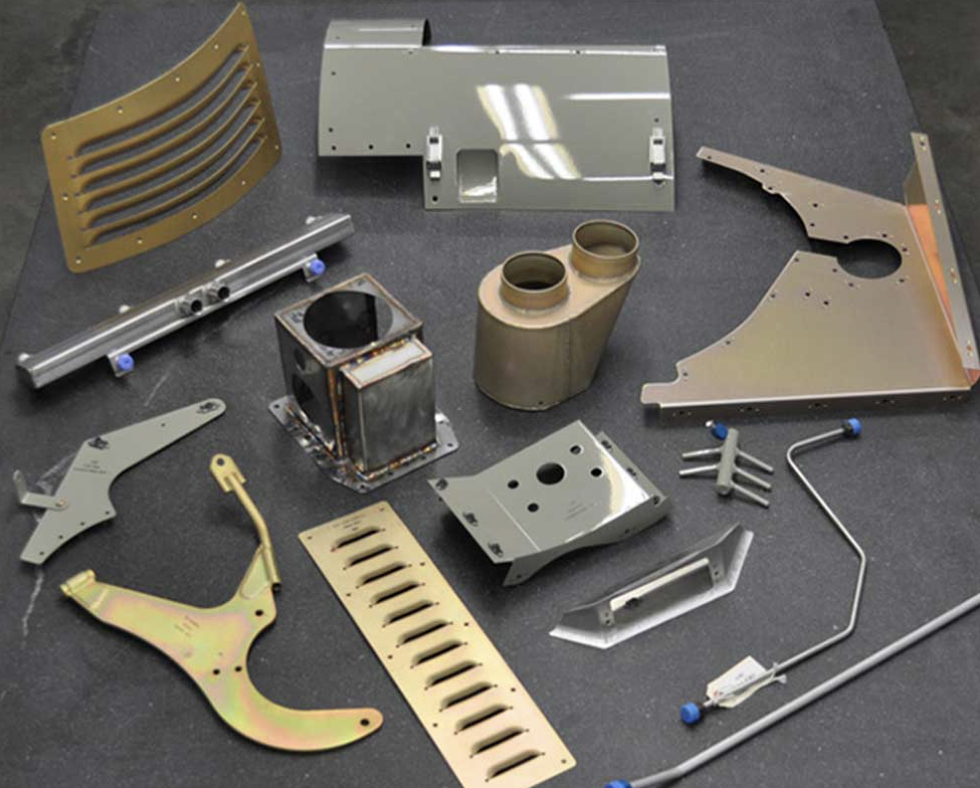

Our area of expertise is manufacturing Sheet Metal Components and Sub-Assemblies for Locomotives, Elevators, Power sectors, Railway, Metro, and Textile Industries requiring processes like punching, piercing, stamping, bending, forming, etc.

We also Design & Manufacture Jigs, fixtures, and forming dies required for production.

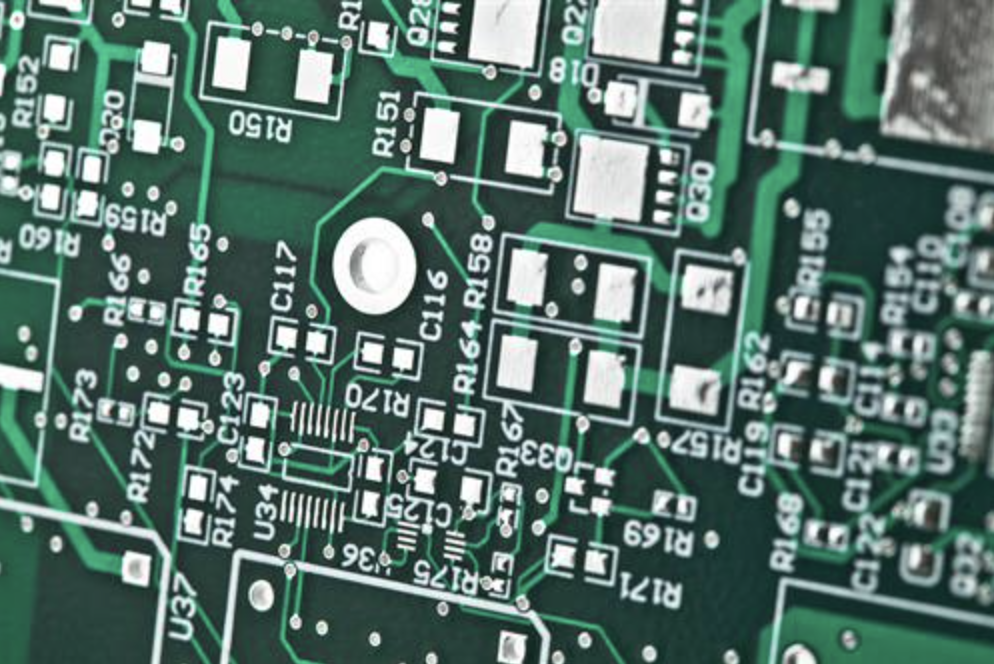

We have the capability to design and manufacture PCBs up to 18 layers with more than 2000 components and upto 25000 connections per board for diverse applications.

949-385-1481

Irvine, CA 92620

amrit@rapidSCsolutions.com